Troubleshooting Commercial HVAC Systems: A Practical Guide for Facility Managers

Commercial HVAC systems are built to handle larger spaces and heavier demands than residential systems, but when something goes wrong, the impact is also bigger. Poor airflow, rising utility costs, or uncomfortable indoor temperatures can slow down productivity, affect customer satisfaction, and even damage equipment inside your building. Knowing how to troubleshoot a commercial HVAC system is essential if you want to maintain efficiency and prevent unexpected shutdowns.

This guide explains common commercial HVAC problems, how to diagnose them step by step, and when it is time to call a professional. It is written for building owners, facility managers, and business operators who want practical solutions that actually work.

How Commercial HVAC Systems Work

Commercial HVAC systems regulate temperature, air pressure, humidity, and ventilation. They are often configured in one of these setups:

- Rooftop units (RTUs)

- Split systems

- Chiller systems

- Heat pump systems

- Variable Refrigerant Flow (VRF) systems

Although the designs differ, every system relies on the same fundamentals: air movement, refrigerant flow, heat exchange, and clean airflow. When one of those components is restricted, the system runs harder and less efficiently, leading to breakdowns and rising energy use.

Common Commercial HVAC Problems

Here are the most frequent issues you might encounter during daily operation:

Inconsistent Heating or Cooling

If certain zones are too warm while others are too cold, this points to major airflow problems. Causes include blocked vents, duct leaks, faulty dampers, or malfunctioning thermostats.

Weak Airflow

Weak airflow usually means the blower motor is underperforming or there is a blockage inside the system. Dirty filters, clogged ducts, or a failing fan motor can cause this.

System Short Cycling

If the HVAC unit turns on and off repeatedly, it could be overheating, low on refrigerant, or suffering from an electrical issue.

Rising Energy Bills

If energy use goes up without a change in weather or occupancy, the system is working harder than it should. Dirty coils, air leaks, and poor controls are often to blame.

Strange Noises

Loud banging, squealing, or grinding noises signal mechanical failure. This may indicate worn belts, loose components, or a damaged blower motor.

Troubleshooting Checklist for Commercial HVAC Problems

Before calling a technician, here are steps you can take to narrow down the problem. These checks are safe and effective and can prevent unnecessary downtime.

1. Inspect Thermostats and Control Systems

Start with the simplest fix. Check thermostat settings and confirm the building automation system (if installed) is operating correctly. Dead thermostat batteries or incorrect programming can shut down heating or cooling unexpectedly.

2. Check Air Filters

Air filters trap dust and debris before they reach HVAC components. But when they clog, airflow drops and the system overheats or freezes. Replace dirty filters immediately. This single step can solve many airflow and temperature issues.

3. Examine Air Vents and Dampers

Blocked supply vents and closed dampers reduce airflow to certain zones. Ensure vents are not covered by furniture, storage, or ceiling obstructions. If your system uses motorized dampers, confirm they are opening correctly.

4. Listen for Equipment Noise

Mechanical sounds are clues. A squealing noise usually means a belt is worn or misaligned. Grinding noises indicate metal-on-metal contact, often caused by a failing motor. Shaking or rattling could mean loose panels or mountings.

5. Check Condenser and Evaporator Coils

Dirty coils restrict heat transfer and increase energy use. If the condenser coils outside are dusty or clogged, clean them safely using a coil cleaner. If indoor evaporator coils are frozen, turn the system off and let them thaw before restarting.

6. Inspect Ductwork

Leaks in ducts waste conditioned air before it reaches its destination. This leads to hot and cold spots and higher utility bills. If you suspect air loss, schedule a duct inspection. You can reduce energy waste significantly with sealing and repair through commercial HVAC services that include duct diagnostics.

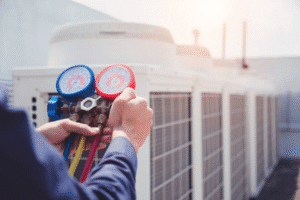

7. Monitor Refrigerant Levels

Low refrigerant prevents proper heat transfer and reduces cooling capacity. If you notice warm air coming from vents, frozen coils, or hissing noises near refrigerant lines, the system may have a leak. Only a licensed technician can handle refrigerant repairs safely.

8. Check Blower Components

If air filters are clean but there is still little airflow, the blower motor or fan belt may be worn out. A stretched or loose belt reduces fan speed. A noisy or overheating motor will eventually fail without service.

Solving High Energy Bills in Commercial Systems

A commercial HVAC system can be responsible for nearly half of a building’s total energy use. If your energy bills are climbing, look at:

- Poor maintenance history

- Miscalibrated thermostats

- Obstructed airflow

- Dirty filters or coils

- Failing motors or compressors

- Poor insulation or duct losses

- Lack of zoning or outdated equipment

You can dramatically improve efficiency by scheduling regular tune-ups through a preventive maintenance plan that keeps components clean, aligned, and optimized.

When to Call a Professional HVAC Technician

Commercial systems are complex and often integrated with building automation. You should contact a professional if:

- There are electrical issues or tripped breakers

- You see refrigerant leaks or low-pressure warnings

- The system is shutting down under normal use

- Major components like the compressor or heat exchanger fail

- No troubleshooting step solves the issue

Professional diagnostics prevent system damage and protect your warranty. If your building has frequent HVAC breakdowns, scheduling routine HVAC repair services is better than waiting for the entire system to fail during peak use.

Preventing HVAC Problems Before They Start

The best troubleshooting approach is prevention. You can avoid costly repairs and system shutdowns by:

- Changing filters monthly or quarterly, depending on system load

- Keeping coils clean

- Inspecting belts, pulleys, and motors

- Testing safety controls and sensors

- Sealing duct leaks

- Verifying thermostat calibration

- Scheduling annual heating and cooling tune-ups

These tasks extend the life of the system and keep energy costs predictable.

Final Thoughts

Troubleshooting commercial HVAC equipment requires a mix of observation, routine maintenance, and understanding how system components affect each other. Start with simple checks like filters and controls, then move toward airflow, electrical, and mechanical components. If the issue goes beyond basic troubleshooting, do not delay service. Commercial equipment failures worsen quickly and often produce higher repair costs the longer they are ignored.

Schedule Commercial HVAC Support

If your commercial HVAC system is not performing the way it should, professional support is the fastest way to get back to comfort and efficiency. Tailored Mechanical services commercial buildings of all sizes and delivers reliable diagnostics, repair, and ongoing maintenance. Keep your business comfortable, safe, and energy efficient with expert commercial HVAC solutions.

Call (520) 808 2743 today to schedule service or request a quote.