How Do I Know If My HVAC Circuit Board Is Bad?

Imagine waking up to a freezing house in winter or sweltering heat in summer both scenarios could indicate an HVAC control board malfunction, the hidden “brain” behind your home’s comfort system.

When your HVAC system’s circuit board fails, it creates more than just discomfort. A faulty control board can lead to:

- Dangerous electrical shorts creating fire hazards

- Complete system shutdown during extreme weather

- Cascading damage to other expensive components

- Unnecessarily high energy bills from inefficient operation

Your HVAC control board coordinates every function from igniting burners to controlling fan speeds. Similar to a computer’s motherboard, it interprets signals from your thermostat and directs the appropriate responses through complex sequencing operations.

Unfortunately, these sophisticated electronic components are vulnerable to power supply issues, thermal expansion, and gradual wear. Recognizing the warning signs early can save you from costly emergency repairs.

Whether you’re facing stuck relay switches, noticing unusual diagnostic LED lights flashing behind your furnace access panel, or experiencing temperature regulation problems, this guide will help you determine if you’re dealing with burned-out circuitry or another issue entirely and when it’s time to call an HVAC repair technician.

Core Signs of a Bad HVAC Circuit Board

Unresponsive HVAC System

You’ve cranked up the thermostat, but your house feels like an icebox. Sound familiar? When your heating or cooling system gives you the silent treatment, your HVAC control board might be staging a quiet rebellion.

Think of your control board as the system’s brain when it stops communicating, nothing works. The most common scenario is flipping that thermostat to “heat” or “cool” and… nothing. Crickets. This thermostat override situation is often the first red flag.

Before you panic, check these power-related issues:

- Is your circuit breaker tripped? (The simplest fix!)

- Has the transformer failure occurred? (This component converts your home’s high voltage to the 24V your HVAC system uses)

- Are all Molex plug connections securely fastened? (These plastic connectors can work loose over time)

Testing your system’s power supply issues is relatively straightforward. With proper safety precautions, you can use a multimeter to check if the board is receiving power. No power despite a working outlet? Your control board might be the culprit.

Diagnostic LED/Warning Lights

Modern HVAC systems are surprisingly chatty if you know how to listen! Behind your furnace access panel lives a secret language of diagnostic LED lights that can tell you exactly what’s wrong.

These tiny HVAC warning lights blink in specific patterns to communicate different issues:

Blink Pattern | Typical Meaning |

1 blink | Thermostat error |

2 blinks | Pressure switch problem |

3 blinks | Ignition failure |

4 blinks | Limit switch issue |

Steady light | Normal operation |

No light | Power or board failure |

Most manufacturers place a code legend right on the inside of your furnace door or control panel. Can’t find yours? Your system’s manual or a quick online search should reveal what those mysterious flashes mean.

When these lights go rogue either staying completely dark or showing error codes that don’t reset after addressing the apparent issue your circuit board might be misinterpreting signals or failing to process them correctly.

Irregular System Behavior

Is your HVAC system behaving like it’s had too much caffeine? Sequencing errors can make your system act downright strange.

The classic symptom is short cycling your system turns on, runs briefly, then shuts off only to restart moments later. This isn’t just annoying; it’s inefficient and stressful on your equipment’s components.

Other weird behaviors that suggest temperature regulation problems include:

- Blower fan running constantly (even when set to “auto”)

- System switching between heating and cooling randomly

- Different zones or rooms experiencing wildly different temperatures

- Furnace igniting but shutting down before completing a heating cycle

These issues often stem from the circuit board’s inability to properly sequence operations or interpret temperature readings correctly. Thermal expansion in circuit boards can cause these intermittent problems, especially in older systems that have endured years of heating and cooling cycles.

Visible Physical Damage

Sometimes, the evidence is right there in plain sight. Pop off that access panel and take a look at your circuit board. Burned-out circuitry leaves telltale marks that even non-professionals can spot.

Visual signs of a failing board include:

- Scorch marks or melted plastic around components

- Bulging or leaking capacitors (those little cylindrical components)

- Cracked solder joints that appear dull or fractured

- Corrosion or rust, especially near terminal connections

Even subtle signs like discoloration around certain components can indicate overheating. If you spot faulty soldering connections those tiny metal joints that connect components to the board you’re likely looking at a board in decline.

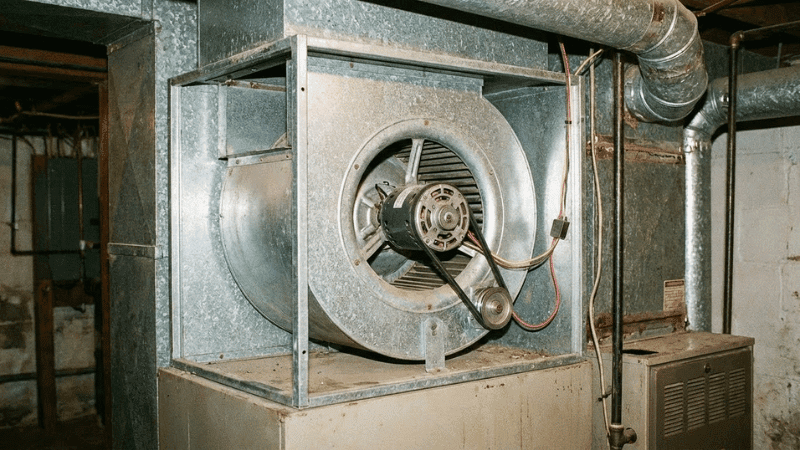

Stuck Relay Switches

Ever hear that distinctive “click” when your HVAC system turns on? That’s a relay switch in action! These electromagnetic switches control the flow of electricity to major components like your compressor or blower motor.

When stuck relay switches occur, they can either remain permanently open (preventing operation) or permanently closed (causing non-stop operation). You might notice:

- Constant humming from your system

- Components that never shut off

- Components that never turn on despite thermostat calls

Relay failure often happens due to electrical surges or the natural wear of these mechanical parts. The clicking sound should be crisp and definitive if you hear buzzing or chattering instead, your relays might be struggling due to insufficient power from a failing control board.

Safety Switch or Sensor Failures

Your HVAC system has numerous safety switches designed to prevent dangerous operating conditions. Your circuit board constantly monitors these switches, shutting down the system if anything seems off.

A properly functioning integrated furnace control (IFC) board can distinguish between an actual safety concern and a sensor malfunction. A failing board, however, might:

- Misinterpret normal conditions as dangerous (causing unnecessary shutdowns)

- Miss actual safety issues (potentially creating hazardous situations)

- Send erratic signals to safety components

Proper safety switch testing requires specialized knowledge and equipment, making this aspect of diagnosis best left to professionals who understand the intricate HVAC sequence of operation.

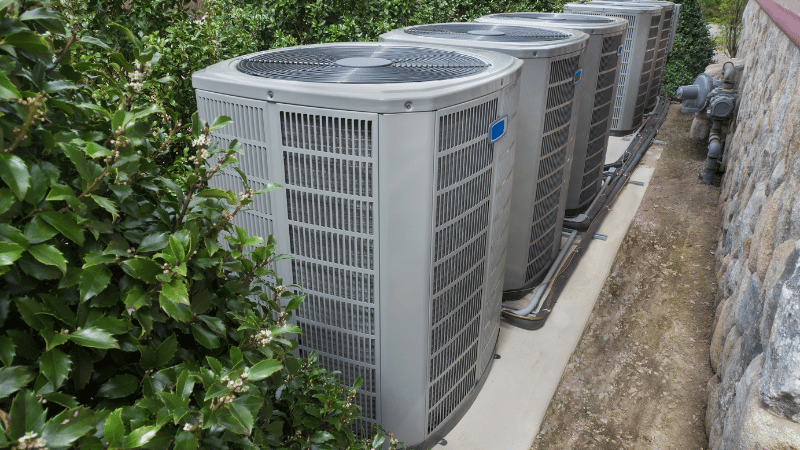

Failed Defrost Cycles (Heat Pumps)

If you have a heat pump, pay special attention to its defrost functionality. In cold weather, your outdoor unit should periodically enter a defrost mode to melt accumulated ice.

A circuit board failure might prevent proper defrost cycling, leading to:

- Ice-covered outdoor coils

- Significantly reduced heating capacity

- Unusual noises from the outdoor unit

- Excessive energy consumption

This particular issue often involves complex ECM motor control problems, which require professional diagnosis using wiring diagrams and advanced testing equipment to properly identify.

Remember, while these signs can point toward control board issues, proper control board troubleshooting often requires professional expertise to pinpoint the exact cause before investing in replacement parts.

Step-by-Step Troubleshooting

Let’s roll up our sleeves and play HVAC detective! Before you call in the cavalry (aka an expensive emergency repair), let’s walk through some control board troubleshooting steps that might save you time and money.

Visual Inspection First

Channel your inner CSI investigator and start with your eyes:

- Power down your system completely (safety first!)

- Remove the furnace access panel (usually secured with simple screws)

- Look for the obvious burned-out circuitry, loose wire connections, or components that resemble toast rather than electronics

- Check all Molex plug connections for secure seating

- Scan for cracked solder joints that appear dull or fractured instead of shiny

Pro tip: Take a photo of your control board before touching anything. This gives you a reference point for where everything should be connected if things get disconnected during your investigation.

The Multimeter: Your New Best Friend

If you own a multimeter (or can borrow one), you’ve got the perfect tool for basic HVAC system diagnostics:

- Set your multimeter to measure AC voltage

- Locate the transformer (typically a small box-shaped component)

- Test for 24V/34V signal testing at the output terminals

- No voltage? Your transformer might be the culprit rather than the board

Remember, your HVAC control board expects a steady diet of low-voltage electricity. If that’s missing, the problem may lie elsewhere!

Component Isolation: Divide and Conquer

Sometimes the best approach is to eliminate suspects one by one:

- Try bypassing your thermostat by connecting the R and W terminals directly (this creates a call for heat, bypassing potential thermostat override issues)

- Listen for relay failure sounds healthy relays make a clear “click,” while failing ones might buzz or chatter

- Remove and inspect any plug-in relays for signs of damage

Professional-Level Diagnostics

For the truly adventurous (and electrically knowledgeable), more advanced troubleshooting awaits:

- Reference wiring diagrams (usually found on the inside of access panels)

- Perform safety switch testing to ensure limit switches aren’t falsely triggering shutdowns

- Test for proper signals at each stage of the HVAC sequence of operation

Show Image A typical integrated furnace control (IFC) board with various connection terminals

Know When to Fold ‘Em

There comes a point when DIY troubleshooting should give way to professional help. If you’re experiencing:

- Repeated failures after reset attempts

- Electrical odors or visible damage

- Issues involving ECM motor control (those advanced variable-speed motors)

- Consistent error codes that don’t respond to basic fixes

…it’s time to call an HVAC repair technician. The good news? Your detective work hasn’t been wasted you’ll be able to describe the symptoms precisely, potentially saving diagnostic time and money.

Remember that modern HVAC systems, especially those with sophisticated gas vs. integrated control boards, represent a significant investment. Sometimes the smartest DIY move is knowing when to call the pros!

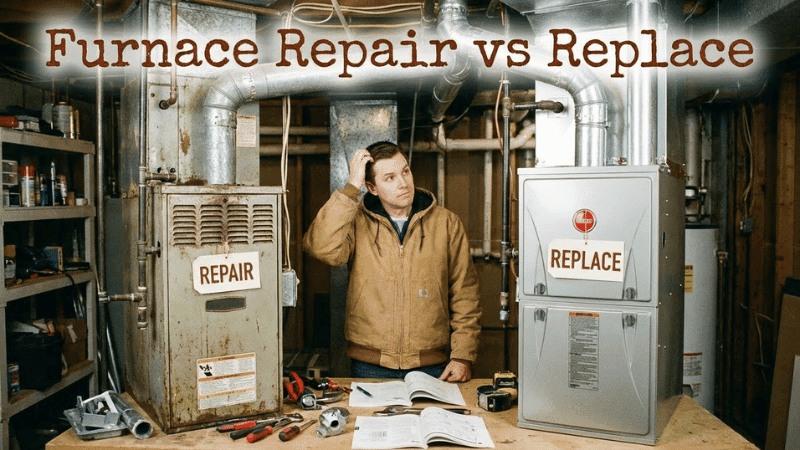

Repair vs. Replacement Guide

So you’ve confirmed your HVAC control board is causing trouble. Now comes the million-dollar question: fix it or ditch it? Let’s break down your options without breaking your bank account!

When Repair Makes Sense

Not all circuit board issues spell doom for your wallet. Consider these repair-friendly scenarios:

- Loose wire connections that simply need reattachment

- Cracked solder joints that a skilled technician can reflow

- Damaged Molex plug connections that can be replaced individually

- Simple relay failure where just one component needs swapping

If you’re handy with electronics, minor fixes like resoldering a loose connection might cost just a few dollars in materials. Even having a technician perform these smaller repairs typically runs $100-200 far less than a full replacement.

“I’ve seen perfectly good systems tossed because of a single bad solder joint. Such a waste!” Veteran HVAC technician

When Replacement Is Inevitable

Sometimes, your board has simply played its final note. Signs it’s time for a replacement control board include:

- Extensive burned-out circuitry across multiple components

- Water or moisture damage penetrating multiple layers

- Boards with obsolete components no longer manufactured

- Failed attempts at repair with recurring issues

The Cost Reality Check

Let’s talk numbers:

Board Type | DIY Cost | Professional Installation |

Basic furnace | $200-350 | $400-600 |

Integrated furnace control (IFC) | $350-500 | $550-800 |

Advanced with ECM motor control | $450-800 | $700-1,200 |

These prices can sting, but remember replacing just the board is still dramatically cheaper than replacing your entire HVAC system (which could run $5,000-10,000).

The DIY Dilemma

Feeling brave enough to tackle a board swap yourself? Consider:

- Wiring diagrams are your non-negotiable best friend

- Take photos before disconnecting anything

- Label wires with tape and markers before removal

- Consider thermal expansion in circuit boards when mounting (don’t overtighten)

The catch? Many manufacturers void warranties if boards aren’t installed by certified HVAC repair technicians. Plus, improper installation can lead to more damage than you started with.

The Compatibility Question

Not all boards are created equal. Modern replacement boards might include:

- Updated components resistant to transistor failure

- Better protection against power supply issues

- More sophisticated diagnostic LED lights

Just be sure your replacement matches your system’s exact specifications—the wrong board is no bargain regardless of price!

Remember: while saving money feels great, some professional HVAC maintenance investments actually save more in the long run by preventing cascading failures throughout your system.

How to Prevent Future Failures

Let’s face it nobody wants to deal with another HVAC control board meltdown anytime soon. The good news? A little preventive TLC goes a surprisingly long way in extending your board’s lifespan. Think of it as healthcare for your home’s comfort system!

The Power Protection Plan

Your circuit board’s worst enemy? Power fluctuations. Here’s your defense strategy:

- Install a dedicated surge protector for your HVAC system (not the $10 power strip kind invest in proper equipment)

- Consider a whole-home surge protector if you live in an area prone to lightning strikes

- Address any flickering lights or other signs of electrical instability in your home

These simple steps help prevent the power supply issues that frequently lead to premature transformer failure and damaged circuits.

Scheduled Maintenance: The Ounce of Prevention

The humble yet mighty annual checkup is your secret weapon against control board malfunctions:

“In 15 years of service, I’ve rarely seen well-maintained systems develop board failures before the 10-year mark.” HVAC veteran technician

During professional HVAC maintenance, technicians can:

- Check for early signs of faulty soldering connections

- Clean dust accumulation that causes thermal expansion in circuit boards

- Test relay switches before they get stuck

- Verify proper operation of all safety systems

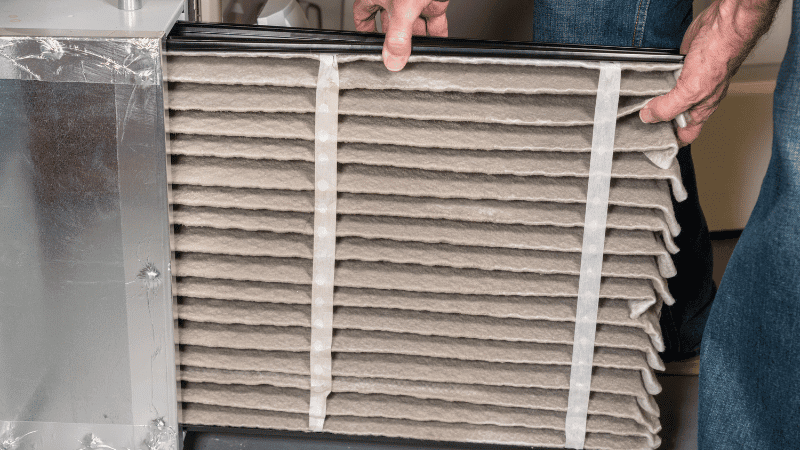

DIY Dust Defense

Between professional visits, you can help your control board breathe easier:

- Change air filters regularly (dirty filters = overworked systems)

- Keep the area around your furnace/air handler clean

- Gently vacuum visible dust from accessible components (with the power OFF!)

- Ensure proper ventilation around your equipment

Moisture: The Silent Board Killer

Water and electronics mix about as well as oil and water. Protect your investment by:

- Addressing any condensate drain clogs promptly

- Keeping humidity levels reasonable throughout your home

- Ensuring outdoor units aren’t being soaked by sprinkler systems

By implementing these straightforward strategies, you’ll dramatically reduce the chance of finding yourself googling “HVAC control board replacement cost” again anytime soon!

When to Call a Professional

DIY troubleshooting has its limits, and sometimes you need to wave the white flag and call in reinforcements. Here’s when it’s time to stop Googling and start dialing an HVAC repair technician:

The Danger Zone

Some situations scream “professionals only”:

- You smell burning electronics or see smoke around your furnace access panel

- Sparks are flying from any component (not the birthday party kind!)

- Your circuit breaker trips repeatedly when the system attempts to run

- You notice unusual electrical “buzzing” sounds coming from the HVAC control board

Complexity Overload

Modern systems especially those with ECM motor control and sophisticated integrated furnace control (IFC) boards are increasingly complex. You’re in over your head if:

- Your system uses proprietary wiring diagrams not available to consumers

- Diagnostics require specialized equipment to interpret HVAC warning lights

- You’re dealing with a “smart” HVAC system connected to home automation

- The HVAC sequence of operation includes variable-speed motors or multi-stage heating

Remember, good technicians can often diagnose a bad board in minutes using their specialized knowledge. That efficiency might cost $75-150 for a service call, but it could save you hours of frustration and prevent accidentally damaging other components.

Think of it this way: You wouldn’t perform your own root canal, right? Some things are worth calling the experts!

Conclusion

We’ve journeyed through the electronic heart of your HVAC system, decoding the mystery behind that finicky HVAC control board! Let’s wrap up what we’ve learned about identifying when this crucial component has decided to retire early.

Remember these key warning signs:

- Diagnostic LED lights flashing like a tiny disco behind your furnace access panel

- An unresponsive system ignoring your thermostat commands

- Physical evidence like burned-out circuitry or cracked solder joints

- Strange behavior including sequencing errors and temperature regulation problems

- The telltale struggle of stuck relay switches

While some minor issues like loose wire connections might be DIY-friendly, most control board troubleshooting ultimately leads to one of two paths: targeted repair of specific components or complete replacement.

Don’t hesitate to call in HVAC repair technician expertise when facing electrical concerns or complex diagnostic challenges. Their specialized knowledge of integrated furnace control (IFC) boards and HVAC system diagnostics can save you time, money, and potential safety hazards in the long run.

Whether you’re facing a simple fix or need comprehensive professional HVAC maintenance, staying attentive to your system’s subtle cries for help can prevent those dreaded no-heat or no-cooling emergencies that inevitably strike during the worst possible weather!

Take action at the first signs of control board issues your comfort, safety, and wallet will thank you.